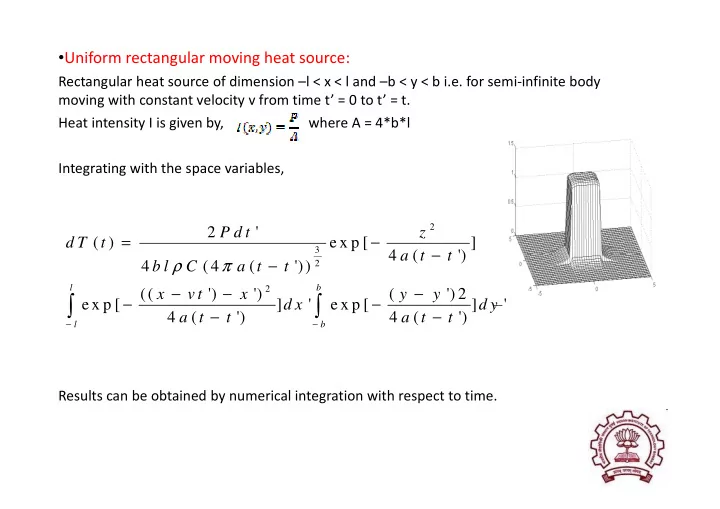

• Uniform rectangular moving heat source: Rectangular heat source of dimension –l < x < l and –b < y < b i.e. for semi-infinite body moving with constant velocity v from time t’ = 0 to t’ = t. Heat intensity I is given by, where A = 4*b*l Integrating with the space variables, 2 2 P d t ' z = − d T ( ) t e x p [ ] 3 3 − − 4 4 a t a t ( ( t t ') ') ρ π − 2 4 b l C ( 4 a t ( t ')) l b 2 − − − (( x v t ') x ') ( y y ') 2 � � − − e x p [ ] d x ' e x p [ ] d y ' − − 4 a t ( t ') 4 a t ( t ') − − l b Results can be obtained by numerical integration with respect to time.

Comparison of Gaussian and uniform heat source: for EN 18 steel Results: Results: No Fig. Comparison of width/depth of hardened zone[13] 1 2 3 4 5

Finite difference formulation: • Nodal points • Nodal network • Regular or irregular • Types - coarser - fine ……Temperature at time interval � t

Finite Element Models 02/08/10

Thermal Modeling – Heat generated in workpiece due to cutting is small compared to the heat generated by the laser – A scaled model (5mm x 2mm x 2mm) is used – The Gaussian distribution of laser power intensity P x,y is given by: � − � 2 2 P 2 r � � � � tot tot = = − P P exp exp � � � � x , y 2 2 π � � r r b b – The average absorptivity of incident irradiation is determined experimentally – Temperature dependent thermophysical properties are used

Mathematical Formulation ������������������������������������������������������� � � � � � � ∂ ∂ ∂ ∂ ∂ ∂ . ∂ ∂ T T T T T � � � � � � + + + = ρ + ρ k k k Q c c V � � p p � � � � ∂ ∂ ∂ � ∂ � ∂ ∂ ∂ ∂ x x y y z z t x ������������������ T(x, y, z, 0 ) = T 0 0 ����������������������������������������� ∂ T 4 4 − + − + σε − = k q h ( T T ) ( T T ) 0 0 0 ∂ n ∂ T − + − 0 = k q h ( T T ) 0 e ∂ n − 3 1 . 61 ���������������� !!!" ����� , = × ε h 2 . 4 10 T e

Mathematical Formulation • Average measured temperatures are used for boundary conditions on remaining external surfaces • Half symmetry used at bottom face = = q q 0 0 bottom bottom

Case Study- Thermal Model 1 ELEMENTS MAT NUM Natural B.C. on front face JUL 19 2006 14:52:01 Y X Y Z X Z Symmetry B.C. on bottom face • Mapped dense mesh (25 µ m x 12.5 µ m x 20 µ m) • An 8 noded 3-D thermal element (Solid70) is used • Gaussian distribution of heat flux applied to a 5x5 element matrix which sweeps the mesh on the front face

Temperature Simulation 1 1 NODAL SOLUTION NODAL SOLUTION JUL 20 2006 JUL 20 2006 STEP=41 STEP=41 10:37:08 10:37:08 SUB =10 SUB =10 TIME=6 TIME=6 TEMP (AVG) TEMP (AVG) RSYS=0 RSYS=0 SMN =150 SMN =150 SMX =1876 SMX =1876 Y Y X X MX MX (Laser scan direction) (Laser scan direction) 150 150 533.653 533.653 917.307 917.307 1301 1301 1685 1685 341.827 341.827 725.48 725.48 1109 1109 1493 1493 1876 1876 #�$���������$%�������������������������&� ��������� '�(�������%������ '� $$)$���������%�������� '� µ $��%�����*�"

Laser Cutting Laser Cutting ME 677: Laser Material Processing Instructor: Ramesh Singh 1

Outline • Materials Processing Parameters • Process Description • Mechanisms of Laser Cutting ME 677: Laser Material Processing Instructor: Ramesh Singh 2

Effect of Power Density • Power density is the key process driver • Power Density (Intensity)= P/ π r 2 ME 677: Laser Material Processing Instructor: Ramesh Singh 3

Process Variables for Material Processing • The other important process variables: ME 677: Laser Material Processing Instructor: Ramesh Singh 4

Interaction Time and Empirical Process Chart • Interaction time, τ = 2 r/v where r = beam radius and v = velocity ME 677: Laser Material Processing Instructor: Ramesh Singh 5

Structural Steel ME 677: Laser Material Processing Instructor: Ramesh Singh 6

Cutting • Laser cutting is able to cut faster and with a higher quality then competing processes: – Punch, plasma, abrasive waterjet, ultrasonic, oxyflame, sawing and milling oxyflame, sawing and milling • Can be automated • 80% industrial lasers in Japan are used for metal cutting ME 677: Laser Material Processing Instructor: Ramesh Singh 7

ME 677: Laser Material Processing Instructor: Ramesh Singh 8

Typical Cutting Setup ME 677: Laser Material Processing Instructor: Ramesh Singh 9

Recommend

More recommend