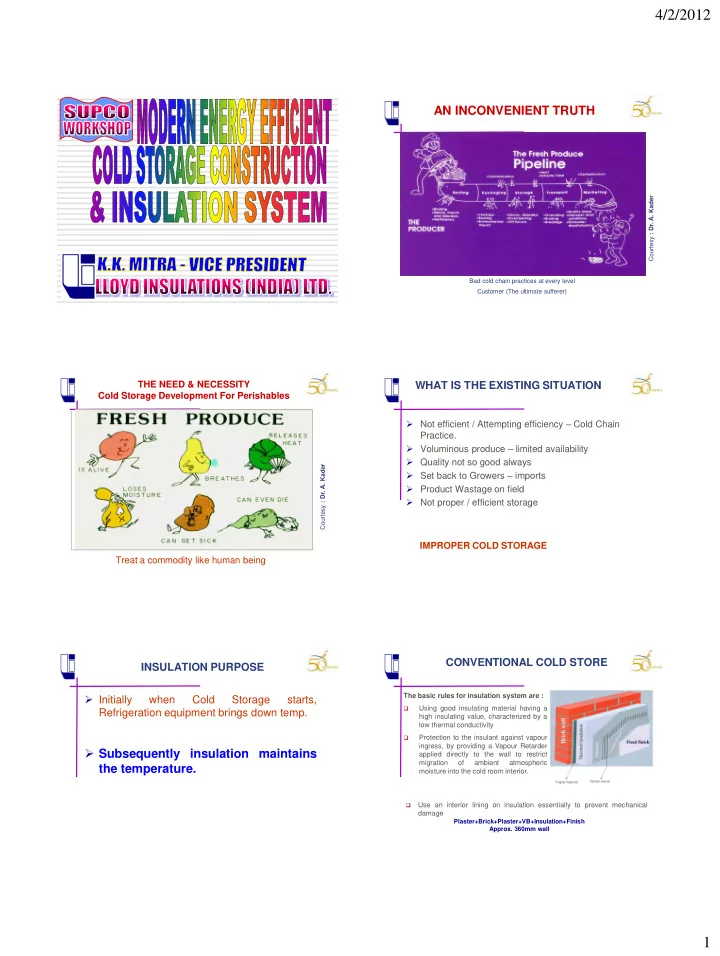

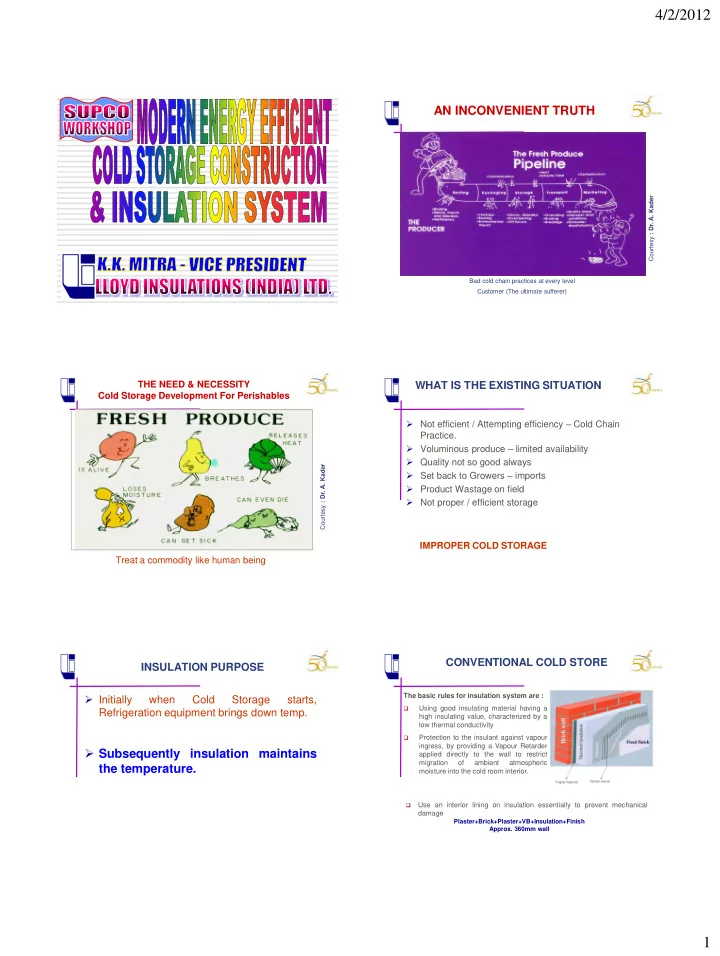

4/2/2012 AN INCONVENIENT TRUTH Courtesy : Dr. A. Kader Bad cold chain practices at every level Customer (The ultimate sufferer) 1 1 THE NEED & NECESSITY WHAT IS THE EXISTING SITUATION Cold Storage Development For Perishables Not efficient / Attempting efficiency – Cold Chain Practice. Voluminous produce – limited availability Quality not so good always Courtesy : Dr. A. Kader Set back to Growers – imports Product Wastage on field Not proper / efficient storage IMPROPER COLD STORAGE Treat a commodity like human being CONVENTIONAL COLD STORE INSULATION PURPOSE The basic rules for insulation system are : Initially when Cold Storage starts, Using good insulating material having a Brick wall Refrigeration equipment brings down temp. high insulating value, characterized by a low thermal conductivity Bitumen Protection to the insulant against vapour ingress, by providing a Vapour Retarder Subsequently insulation maintains applied directly to the wall to restrict migration of ambient atmospheric the temperature. moisture into the cold room interior. Use an interior lining on insulation essentially to prevent mechanical damage Plaster+Brick+Plaster+VB+Insulation+Finish Approx. 360mm wall 1

4/2/2012 EXISTING COLD STORE – PROBLEMS, EXISTING COLD STORE – PROBLEMS CONVENTIONAL PRACTICE CAUSES OF THERMAL Sequential application of INSULATION SYSTEM vapor barrier, insulation & FAILURE plaster finish Continuous moisture ingress through plaster Brick wall Insulation becoming wet & What about moisture resistivity decreases ingress from inside & Plaster chipping off life of plaster finish Bitumen Vapour barrier becomes weak Formation of cold spots Deterioration & failure of Thermal Insulation System Basic Thermal & Civil DOUBLE MOISTURE ATTACK Engg. Design problem 1 % OF MOISTURE INGRESS = 5 % REDUCTION IN ‘R’ VALUE EXPANDED POLYSTYRENE (EPS) EXPANDED POLYSTYRENE (EPS) TECHNICAL SPECIFICATIONS TECHNICAL SPECIFICATIONS Chemical Inertness - Unaffected by water, acids, alkalies, alcohols and most oils of DENSITY - 18 to 22 kg/m3. Higher densities available on request vegetable and animal origin. Soluble in aliphatic, aromatic and chlorinated hydrocarbons, ketones, esters, ethers, petrol, turpentine, Temperature range - - 200 deg.C to 80 deg.C concentrated sulphuric and nitric acids Thermal conductivity - The air entrapped within the minute closed cells impart to the material its extraordinarily low thermal conductivity 0.314 W/mK at 10 0 C mean temp. Handleability - Easily cut with a knife and readily applied with solvent free bitumen and adhesive Compressive Strength - 0.7 to 1 kg/m2 at 10% deformation Slabs – 1M x ½ M of thickness 25mm to 100mm Standard Sizes - Cross Breaking Strength 1.4 to 1.8 kg/m2 Pipes – ½M length of thickness 15 to 150mm Other sizes and thicknesses available on request. Water Absorption - Less than 0.5% by volume • (after 24 hrs. immersion) Draw backs - Moisture gets entrapped between cells and ice formation, leads to failure gradually. • Low density • Poor compressive strength • Poor adhesion • Lower temp. rating 9 10 Suppose if Insulation is changed INSULATION LIFE Insulation needs to be properly fixed to surface Changing from Open Cell Insulation needs to be covered & protected Structure to Closed Cell Cold Insulation needs vapour barrier on warm side Insulation materials Brick wall Polyurethane Foam Slabs with Thermal insulation aluminium foil Cold adhesives Proper Thickness (70 ->85- 90% RH) Cold storage Insulation needs vapour PPGI sheet finish Supporting Structure PPGI Sheet barrier on both sides to counter moisture Polymerized plaster Vapour Barrier Overlapping joints attack on both sides. Thermal Engineering issue 2

4/2/2012 Suppose if Insulation is changed Basics Polyurethane & Polyisocyanurate Foams : Jointing problem will persist. Manufactured out of a very fast chemical exothermic PPGI sheet finish, conduction losses from back reaction between two chemicals in presence of a up support / cold spots blowing agent resulting into a polymer matrix & gas Moisture ingress thru joints. filled closed cells all around Labour intensive application. Partial solution Poor aesthetics Polymerized plaster & PUF Basics High Performance Closed Cell Insulation Material Gas filled air cells has very low conductivity which Polyurethane & Polyisocyanurate Foams - reduces heat conduction Lowest thermal conductivity (0.021 W/mK) Smaller size of cells reduces convection Adequate density (32-36 kg/m3 for Slabs, 40-45 Every cell acts as a barrier to radiative heat loss kg/m3 for panels) Some air does enter the blowing agent cells and fills Higher temperature rating (110-140 deg.C) up thru aging Higher Resistance Values Thermal conductivity slightly changes – aging (0.017 CFC, HCFC & ZERO ODP to 0.021 W/mK) Low embodied energy Indigenously manufactured (within 500 kms. any site) Green Insulation – 5 Points UPGRADED INSULATION SYSTEM Basics Extruded Polystyrene Foams : 1) Masonry Light Petrochemical beads / globules compressed & 2) Adhesive cured with steam 3) Polyurethane/PIR Foam 4) Basecoat Expanded has permeable faces & Extruded partially / 5) Fiber mesh easily damageable impermeable faces 6) Top Coat Lower temperature ratings 70 0 C (max.) Higher manufacturing / embodied energy Low density Extruded still primarily imported ETICS : Upgrade conventional insulation practice Primarily cold climate product 18 18 3

4/2/2012 UPGRADED INSULATION SYSTEM Insulation applied on Wall Existing Cold Stores Direct application of PUF insulation on plastered walls from inside or outside. Polymerized Plaster with reinforcement. Painting 1. External Plaster 2. Bricks Existing Cold Stores with sound civil 3. Special adhesive for PUF construction – Revamping of Insulation 4. PUF Insulation slab 5. Polymerized Plaster or Tile REVAMPING OF EXISTING COLD REVAMPING OF EXISTING COLD STORES STORES WALL INSULATION WITH PUF / PIR SLABS WALL INSULATION WITH PUF / PIR SLABS APPLICATION OF PRIMER COAT APPLICATION OF ADHESIVE REVAMPING OF EXISTING COLD REVAMPING OF EXISTING COLD STORES STORES WALL INSULATION WITH PUF / PIR SLABS WALL INSULATION WITH PUF / PIR SLABS APPLICATION OF ADHESIVE FIXING OF SLAB ON TO THE WALL 4

4/2/2012 REVAMPING OF EXISTING COLD REVAMPING OF EXISTING COLD STORES STORES WALL INSULATION WITH PUF / PIR SLABS WALL INSULATION WITH PUF / PIR SLABS FIXING OF SLAB ON TO THE WALL STAGGERED JOINTS REVAMPING OF EXISTING COLD REVAMPING OF EXISTING COLD STORES STORES WALL INSULATION WITH PUF / PIR SLABS WALL INSULATION WITH PUF / PIR SLABS APPLICATION OF BASE COAT APPLICATION OF BASE COAT 28 REVAMPING OF EXISTING COLD REVAMPING OF EXISTING COLD STORES STORES WALL INSULATION WITH PUF / PIR SLABS WALL INSULATION WITH PUF / PIR SLABS FIXING OF REINFORCEMENT MESH FIXING OF REINFORCEMENT MESH 29 30 5

4/2/2012 REVAMPING OF EXISTING COLD REVAMPING OF EXISTING COLD STORES STORES WALL INSULATION WITH PUF/PIR (EXTERNAL) WALL INSULATION WITH PUF / PIR SLABS APPLICATION OF TOP COAT FINAL FINISH 31 32 REVAMPING OF EXISTING COLD Insulation applied inside STORES Existing Cold Stores Direct application of PUF insulation on plastered walls from inside. Polymerized Plaster with reinforcement. Painting Existing Cold Stores with sound civil WALL INSULATION WITH PUF/PIR (EXTERNAL) construction – Revamping of Insulation FINAL FINISH MODERN PRACTICE IN COLD STORE CONSTRUCTION Thickness 80 to 100/ 150 mm. Total thickness: 360mm What is the Solution to achieve efficiency Brick wall Replaced with in Bitumen Cold Store construction Moist/We t PUF Panels Conventional Modern 6

4/2/2012 DESIGN TREND IN MODERN COLD MODERN COLD STORE STORES MATERIALS : Prefabricated Polyurethane Foam sandwich panel Metal sheet finish – solid barrier on both sides Energy efficient insulation Scientifically designed edges, camlocks Steel Structure / PEB 1. PUF Panel 2. Metal facing MODERN COLD STORE MODERN COLD STORE Modular Cold Store Modern practices in cold store DESIGN TREND IN MODERN COLD construction STORES ADVANTAGES : Thermal & vapour barrier metal finish panels Easy to install Less labour intensive Fire Safe Fast construction Energy efficient In practice in India since 1994 / 97 Pre-engineered – Prefab Construction 7

Recommend

More recommend