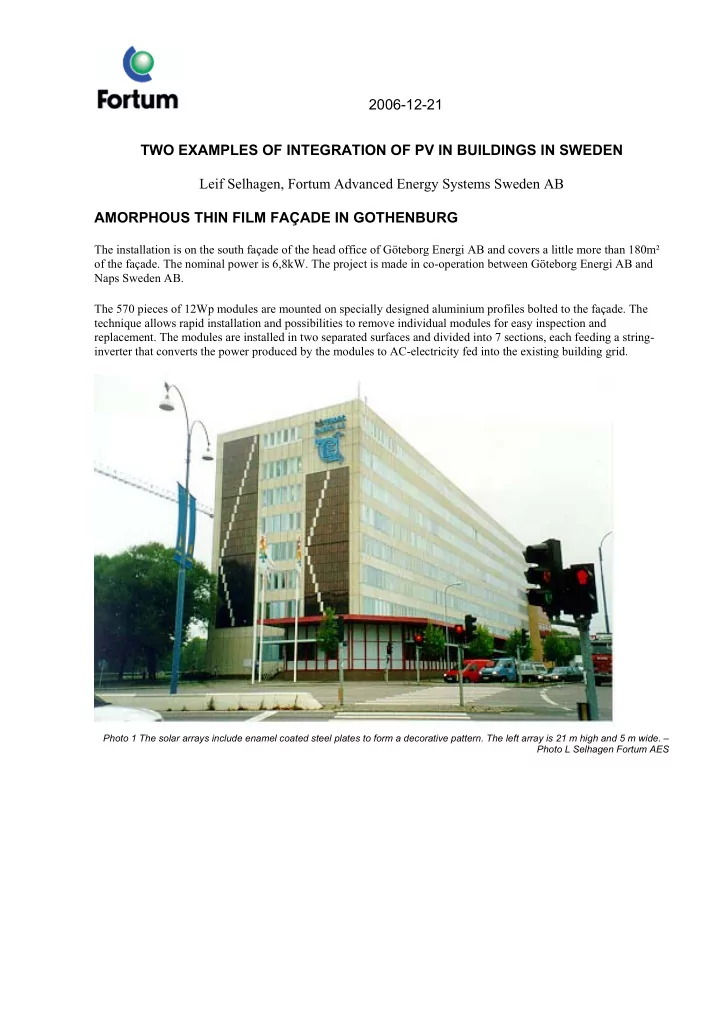

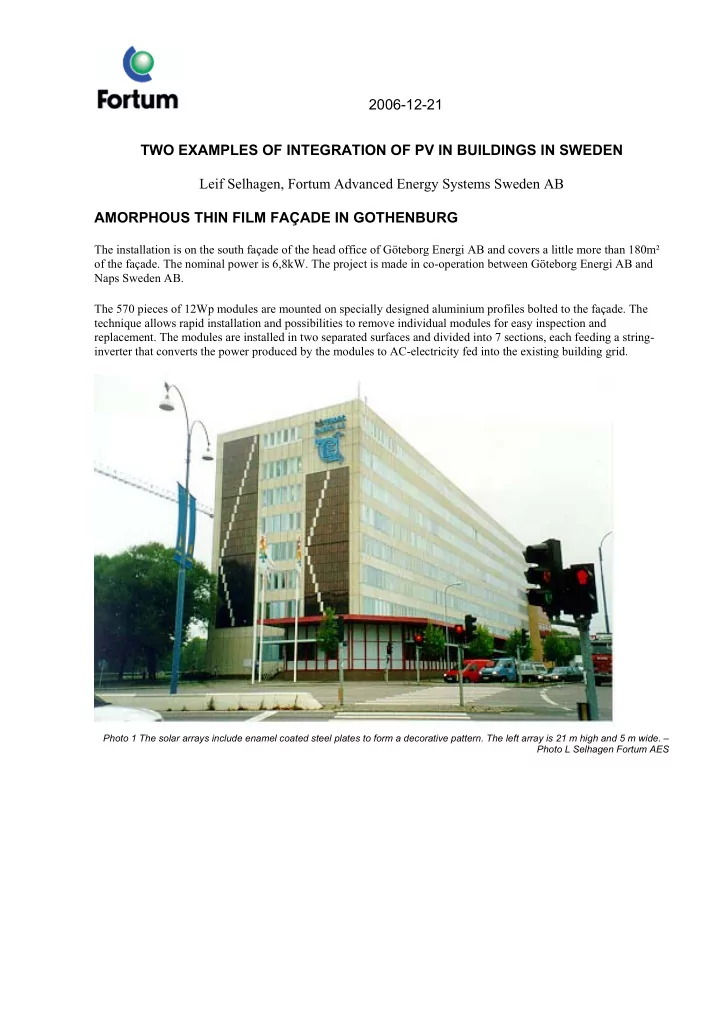

2006-12-21 TWO EXAMPLES OF INTEGRATION OF PV IN BUILDINGS IN SWEDEN Leif Selhagen, Fortum Advanced Energy Systems Sweden AB AMORPHOUS THIN FILM FAÇADE IN GOTHENBURG The installation is on the south façade of the head office of Göteborg Energi AB and covers a little more than 180m² of the façade. The nominal power is 6,8kW. The project is made in co-operation between Göteborg Energi AB and Naps Sweden AB. The 570 pieces of 12Wp modules are mounted on specially designed aluminium profiles bolted to the façade. The technique allows rapid installation and possibilities to remove individual modules for easy inspection and replacement. The modules are installed in two separated surfaces and divided into 7 sections, each feeding a string- inverter that converts the power produced by the modules to AC-electricity fed into the existing building grid. Photo 1 The solar arrays include enamel coated steel plates to form a decorative pattern. The left array is 21 m high and 5 m wide. – Photo L Selhagen Fortum AES

2006-12-21 Page 2(8) L Selhagen HORIZONTAL ALUMINIUM PROFILE VERTICAL SUPPORT BAR AIR GAP WALL SOLAR PANELS Figure 1 The modules are installed between the two aluminium profiles and are standing by its own weight. The thin-film modules, or as we call them - façade-elements, are a further development of our standard amorphous modules. The main changes from the standard design are: � The frame is designed to be compatible with the specially developed aluminium mounting profile. � The lamination technique is changed to one which gives more technical strength. As the glass pieces normally remain stuck to this new lamination material, there is considerably less tendency to shatter on impact, which we feel to be important safety feature for large area PV façade areas. The lamination technique also provides significantly better environmental protection to the thin film solar cell, thus increasing the service life. ______________________________________________________________________________________________ Fortum AES SWEDEN AB Phone: 08-449 59 30 P.O.Box 26 Telefax 08-740 50 01 S-127 21 SKÄRHOLMEN E-mail: leif.selhagen@fortum.com www.fortumsolenergi.com Sweden VAT NO. 556326-5338 C:\Documents and Settings\All Users\Dokument\databas\Kristianstad\Presentation gtb och kst.doc

2006-12-21 Page 3(8) L Selhagen 10.0 mm + 40 mm 10.0 mm back glass front glass solar cell layers back side 923 mm - lamina tion and framing plastic 313 mm Figure 2 Four inverters are installed at floor 4 and three inverters at floor 5. All inverters are connected to the grid via switches and circuit breakers to form a 3-phase AC system. ______________________________________________________________________________________________ Fortum AES SWEDEN AB Phone: 08-449 59 30 P.O.Box 26 Telefax 08-740 50 01 S-127 21 SKÄRHOLMEN E-mail: leif.selhagen@fortum.com www.fortumsolenergi.com Sweden VAT NO. 556326-5338 C:\Documents and Settings\All Users\Dokument\databas\Kristianstad\Presentation gtb och kst.doc

2006-12-21 Page 4(8) L Selhagen Goteborg Energi facade Sketch diagram only, not to scale revised layout following meeting 10.6.1998 JYLE 3.7.1998 Total modules: 570 No of inverters: 7 Total kWp: 6.84 (nom) / 6.161 (temp corrected) indicates blank (metal piece same size as a module), total amount 38 pieces indicates position of a 6 cm break (air gap) T = temparature sensors T (no solar panels in central window area) (area occupied by logo) Section 4 Section 5 T o solar radiation sensor inlet to 4th floor Section 1 T x x x inlet of the all sub-array cables outdoor display taken to central points cables (approx at level of Section 6 floor 4) Section 3 Section 2 Section 7 22 rows of 15 modules + 1 blank 16 rows of 15 modules + 1 blank 330 modules total 240 modules total arranged as 4 sub-arrays arranged as 3 sub-arrays 10 series x 10 parallel (SMA850) 10 series x 5 parallel (SMA700/125-250 VDC) 10 series x 10 parallel (SMA850) 10 series x 10 parallel (SMA850) 10 series x 8 parallel (SMA850) 10 series x 9 parallel (SMA850) 10 series x 5 parallel (SMA700, 125-250VDC) blank metal pieces, 16 pieces blank metal pieces, 22 pieces Height (approximate) Height (approximate) 22 x 0.945m + 2 x 0.06 m + 0.03 m + 0.05 16 x 0.945m + 0.06 m + 0.03 m + 0.05 20.99 m 15.26 m Width (approximate) Width (approximate) 16 x 0.313m 16 x 0.313m 5.008 5.008 ______________________________________________________________________________________________ Fortum AES SWEDEN AB Phone: 08-449 59 30 P.O.Box 26 Telefax 08-740 50 01 S-127 21 SKÄRHOLMEN E-mail: leif.selhagen@fortum.com www.fortumsolenergi.com Sweden VAT NO. 556326-5338 C:\Documents and Settings\All Users\Dokument\databas\Kristianstad\Presentation gtb och kst.doc

2006-12-21 Page 5(8) L Selhagen The system is monitored by two separate supervisory systems. We can call the first for the ”more scientific” system. It measures parameters both on the DC-side and AC-side on one of the blocks of the array. It also measures solar radiation, ambient temperature and solar cell temperatures, the last one at three different levels. The total power and energy are also measured. All this data is collected in a data-logger which can be accessed via a special cellular phone for checking and collection of parameters and operation. The logging system provides enough data to enable evaluation of the system efficiency etc. The second system is more for the staff responsible for maintenance and supervision, where all inverters can be monitored simultaneously. The system is calculated to produce 4.2 kWh/year (AC) and an out-door display will be installed later that shows the actual power produced. CRYSTALLINE MODULES ON FACADE AND ROOF IN KRISTIANSTAD Photo 2 The two houses with their PV systems on wall and shed roofs. Photo L Selhagen Fortum AES The site consists of two identical houses with BIPV systems. The facade consists of 29 100Wp multi crystalline modules and the roof has 30 modules. The modules are connected by 10 in series, except the upper string of the facade that has 9 modules in series. Each string is connected to an 850Wnom string-inverter, which gives a total of 6 inverters for each house. The inverters are installed in the attic. The facade modules are provided with hook-on structures that are rivited on the module frames. ______________________________________________________________________________________________ Fortum AES SWEDEN AB Phone: 08-449 59 30 P.O.Box 26 Telefax 08-740 50 01 S-127 21 SKÄRHOLMEN E-mail: leif.selhagen@fortum.com www.fortumsolenergi.com Sweden VAT NO. 556326-5338 C:\Documents and Settings\All Users\Dokument\databas\Kristianstad\Presentation gtb och kst.doc

2006-12-21 Page 6(8) L Selhagen Photo 3 Hook on structure fixed to the solar module Photo L Selhagen Fortum AES U-profiles are installed on the facade with pre-installed nylon covered bolts. The modules are easily hooked onto the bolts at installation. All modules have quick-connectors to simplify the installation and a prefabricated earthing wire that is attached by self-tapping screws. The feeder cables to the inverters are installed in the protected area behind the modules. This method allows for individual replacement of modules afterwards and the installation is very efficient and fast. The modules can however be reached from ground if using a ladder. Three separate locking rods in stainless steel are therefore installed. The rods locks two vertical rows of modules when turned 180° after all modules are installed. The rod has eccentric discs that fill the 18 mm gaps between the modules and is then locked by padlock. Photo 4 Modules hooked on to the u-profile system - Photo L Selhagen Fortum AES The solar array is integrated in the brick wall that has the same design in colours as the other facades in the area. The inverters and mains connection board are installed in the attic at the wall just behind the top module. ______________________________________________________________________________________________ Fortum AES SWEDEN AB Phone: 08-449 59 30 P.O.Box 26 Telefax 08-740 50 01 S-127 21 SKÄRHOLMEN E-mail: leif.selhagen@fortum.com www.fortumsolenergi.com Sweden VAT NO. 556326-5338 C:\Documents and Settings\All Users\Dokument\databas\Kristianstad\Presentation gtb och kst.doc

2006-12-21 Page 7(8) L Selhagen The roof is a standard folded steel roof. The foundation for the modules consists of standard mounting material in galvanised steel that are fastened on the folders without holes trough the steel sheets. Vertical galvanised steel U-profiles are bolted on the fasteners. Special designed S-profiles are then bolted to the U-profiles. The S-profiles are mounted horizontally. The modules are then slided between the S-profiles and quick connectors are also used for the roof modules. Each row consists of 5 modules. Individual earthing of the modules are not necessary as the modules are in contact to the profiles. Earthing wires are however attached to each profile. Photo 5 Fixing detail for the roofs Photo L Selhagen Fortum AES Photo 6 Detail of modules mounted in S-profile. Photo L Selhagen Fortum AES ______________________________________________________________________________________________ Fortum AES SWEDEN AB Phone: 08-449 59 30 P.O.Box 26 Telefax 08-740 50 01 S-127 21 SKÄRHOLMEN E-mail: leif.selhagen@fortum.com www.fortumsolenergi.com Sweden VAT NO. 556326-5338 C:\Documents and Settings\All Users\Dokument\databas\Kristianstad\Presentation gtb och kst.doc

Recommend

More recommend