Rotating Equipment Luke Kirwin, Business Development Engineer

Rotating Equipment Repairs Pumps Screw conveyors Shafts Fans & Blades

Damages may include … Pumps General erosion General corrosion Galvanic corrosion Cavitation Entrainment Chemical attack

Pumps: Chemical co, Texas, 2007 Chemical attack Chemical attack to wastewater pump Pump replaced annually Belzona solution applied 2 years later still in excellent condition

Pumps: Localized damage • Pump used to transport clay slurry suffered from severe erosion in the pump casing • Back plates were rebuilt and then the system was coated with a Belzona 1300 series product to provide erosion resistance • The repair was 80% less the cost of replacing the system

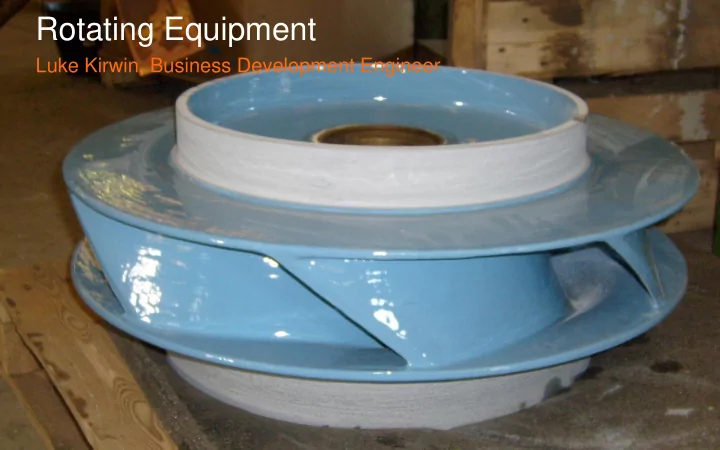

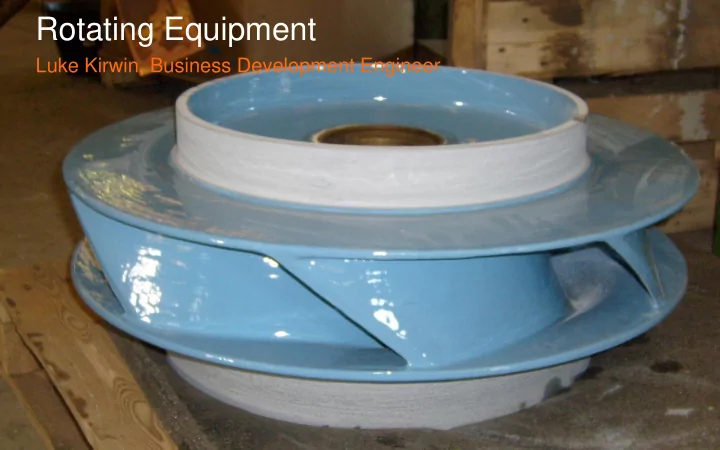

Pumps: Cavitation resistance Chemical plant, Italy, 2007 ▪ Impellors were only lasting 6 months due to heavy cavitation leading to regular replacement of the system ▪ Belzona elastomer system Efficiency coating applied Blasted Surface applied providing excellent cavitation resistance ▪ Pump inspected more than 2 years on and still in perfect condition 2 nd Cavitation resistant coating Cavitation resistant coating

Gold Mine, Guatemala, 2006 Pumps: Abrasion resistance • Pump subjected to severe abrasion from suspended solids leading to through wall abrasion • Pump was rebuilt and coated with a ceramic carbide coating to deal with the abrasion • Welding wasn’t an option here for the customer

Pump efficiency improvement Pumps Belzona 1341 (Supermetalglide) provides a surface 15 times smoother than polished stainless steel, proving to increase efficiency by up to 6% on new pumps.

Ceramic coated WW pumps in Grundfos

Q-H B1341 Q-Eta_gr_B1341

Shaft Repairs GAJAH ANNUAL REPORT 2015 | 12

Shaft Repair Common problems and solution Caused by • Particle contamination • Misalignment • Impact & Vibration • Corrosion • Bearing seizure • Loss of lubrication Conventional solutions are limited • Weld Repair Distortion and hot work required • Flame Spray Requires specialist equipment • Replacement Dismantling of equipment is required

Shaft Repair Belzona solutions Quickly reinstate failed or damaged • equipment Exact profiles can be restored with • the use of forming or machining techniques High adhesion and excellent • mechanical properties such as compressive strength and resistance to erosion

Shaft Repair Belzona Solutions – Forming & Machining

Shaft Repair Shaft rebuilding

Shaft Repair: Submersible Pump Wales, 2007

Shaft Repair Chemical plant, Italy, 2007 Problem: ▪ Bearing spun on the rock crusher ▪ If not back in service → entire quarry and cement plant would shut down ▪ Conventional solution: ▪ Welding Pictures ▪ Replace shaft Solution: ▪ Use of Belzona paste grade material ▪ Easy application using a former ▪ Cold application / In situ repair ▪ Application still in perfect conditions after 2 years!

Shaft Repair: Housing Housing repairs

Shaft Repair: Housing • Bearing housing was severely worn down from heavy loading • Housing was grit blasted and the new bushings were applied with release agent before a 1000 series paste grade was used to repair and rebuild the housing • Welding/machining was considered but it would have stressed the metal. The Belzona solution also offer a quick return to service

Shaft Repair: Housing Recycling facility, USA

Shaft Repair: Keyway Keyway repairs

Shaft Repair: Keyway Water supply company, Bulgaria

Shaft Repair: Keyway • Shaft and keyway worn and damaged on a jaw crusher used to process minerals • Keyway was rebuilt through a milling process • Belzona 1000 series paste grade used to repair the shaft • Belzona saved the customer a lot of time

Screw Conveyor Common Problems • Heavy abrasion caused by wet and dry particles • Flight area of the screw conveyor can be very suspectable to abrasion and can become damaged easily

Screw Conveyor Conventional repair methods • Replacing the system • Expensive • Welding + Machining • Requires specialist tools • Time consuming • Requires Hot work • Belzona solutions are cold applied, easy to use, durable and a fast return to service

Scotland – Screw Conveyor Repair Screw Conveyor Problem: ▪ High level of abrasion of an auger screw was causing the customer to replace the system every year ▪ Welding / hard facing was considered however deemed too expensive and time consuming Solution: ▪ Belzona 1000 series ceramic used to rebuild and protect the flights ▪ Still in excellent condition 3 years later ▪ Customer had even doubled the output of the equipment since the application

Screw Conveyor Pulp & Paper, Portugal, 2016 • Previous screw conveyors were only lasting 6 months due to severe abrasion • Conveyor was blasted and then coated with a Belzona 1800 series ceramic carbide coating • Customer was so happy with the results a second screw conveyor was also coated to protect against abrasion

Screw Conveyor Lithuanian – Screw (Coal transporter) Repair Problem: ▪ Severe abrasion ▪ Customer needed an effective protection system ▪ Conventional repair: Welding every time the metal wears away Pictures Solution: ▪ Belzona 1800 series product: Highly abrasion resistant ceramic carbide filled epoxy ▪ Can rebuild the substrate and protect it against abrasive attack.

France – Screw Conveyor Repair Screw Conveyor Problem: ▪ 11 meters long Stainless-Steel screw conveyor ▪ Abrasion of welded flights Pictures ▪ Welding of the screw every 12 months ▪ Current service life - 5 years Solution: ▪ Belzona Alumina tiles & Belzona 1800 series product ▪ After 12 months; no visible signs of abrasion or wear from the tiles or any detachment

Fans & Blades Problems: Dust Particles, Erosion, Corrosion, Chemical Attack Belzona solutions: Rebuild lost structure, apply coating to prevent further erosion/corrosion Benefits: Reduced downtime, in-situ repair, cold applied

Mining, Portugal, 2018 Fans & Blades: Blower • Heavy corrosion and erosion on the blower of an air compressor • Lost material was rebuilt with a Belzona erosion resistant paste grade then coated with a chemical resistant coating • Cold applied system, eliminating hot work

Fans & Blades: Fertilizer Company, Portugal, 2015 Fan • General erosion on the fan causing a loss of material on the fan blades and edges • Belzona erosion resistant paste grade used to rebuild along ceramic carbide system and finally coated with a fluid-grade coating

Fans & Blades: Cooling tower blade • Leading edge of a cooling tower fan blade eroded due to high speed rotation, impact of water particles and suspended solids • Surface preparation: Grit blasting • Lost material was rebuilt with 1000 series product then 2 coats of 1300 series erosion- corrosion resistance material

Fans & Blades: Agitator blade • Customer needed protection against Abrasion, High temperatures and Chemical attack • Surface of the blades were blasted and rebuilt with 1000 series high temperature paste grade • 2 coats of Belzona 4000 series high temperature, high chemical resistant coating were applied

Rotating Equipment Metal repair composites for in-situ rebuilding of rotating equipment Application: In-situ Cold applied Solvent free Fast curing Hand applied application No hot work No shrinkage Minimal downtime In-service performance: Excellent erosion Very high Self High adhesion Long-term resistance compressive lubricating solution strength Low friction

CASE STUDY 1 Belzona extends the life of mixing blades Slovakia, 2018 Before After 12 months

APPLICATION SITUATION A plaster production factory was using special anchors for mixing

PROBLEM Heavy erosion, without any protection, meant a mixing anchor lasted about 3 months. Conventional welding of hard steel wear plates was very complicated.

SOLUTION 1. Surface prepared 2. Belzona 9811 alumina tiles bonded to surface of the blades 3. Grouted with Belzona 1812

OUTCOME Successful 6 month trial proved no damage Picture of mixing blades after 12 months in service Customer requested all future anchors protected with Belzona abrasion resistant systems

CASE STUDY 2 Large gearbox restored with Belzona Kosice, Slovakia, 2006 Before After

APPLICATION SITUATION Large gearbox used in production of steel plate

PROBLEM Wear in the bearing housing was causing vibration. Conventional welding required the gear box to be out of service too long.

SOLUTION 1. Accurate measuring for alignment was a key feature of the process

SOLUTION 2. Surface prepared and cleaned 3. Belzona 1111 used to rebuild the housing 4. Machining was able to be done in situ to an accuracy of +/-0.03mm.

OUTCOME Easy to apply and machine in situ Belzona method achieved exact alignment ensuring smooth performance of the gearbox.

Recommend

More recommend