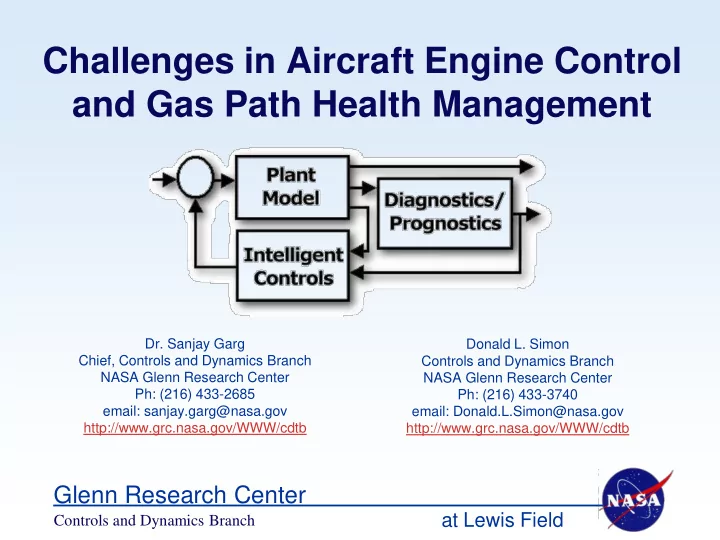

Challenges in Aircraft Engine Control and Gas Path Health Management Dr. Sanjay Garg Donald L. Simon Chief, Controls and Dynamics Branch Controls and Dynamics Branch NASA Glenn Research Center NASA Glenn Research Center Ph: (216) 433-2685 Ph: (216) 433-3740 email: sanjay.garg@nasa.gov email: Donald.L.Simon@nasa.gov http://www.grc.nasa.gov/WWW/cdtb http://www.grc.nasa.gov/WWW/cdtb Glenn Research Center at Lewis Field Controls and Dynamics Branch

Challenges in Aircraft Engine Controls Dr. Sanjay Garg Chief, Controls and Dynamics Branch NASA Glenn Research Center Ph: (216) 433-2685 email: sanjay.garg@nasa.gov http://www.grc.nasa.gov/WWW/cdtb Glenn Research Center at Lewis Field Controls and Dynamics Branch

Outline • Fundamentals of Aircraft Engine Control • Intelligent Engine Concept – from a controls perspective • Advanced Engine Control Logic • Active Component Control • Distributed Engine Control • Summary Glenn Research Center at Lewis Field Controls and Dynamics Branch

Turbofan Engine Basics N2 LPC - Low Pressure Compressor HPC - High Pressure Compressor HPT - High Pressure Turbine LPT - Low Pressure Turbine N1 - Fan Speed N2 - Core Speed N1 • Dual Shaft – High Pressure and Low Pressure • Two flow paths – bypass and core • Most of the thrust generated through the bypass flow • Core compressed air mixed with fuel and ignited in the Combustor • Two turbines extract energy from the hot air to drive the compressors Glenn Research Center at Lewis Field Controls and Dynamics Branch

Basic Engine Control Concept • Objective: Provide smooth, stable, and stall free operation of the engine via single input (PLA) with no throttle restrictions • Reliable and predictable throttle movement to thrust response • Issues: • Thrust cannot be measured • Changes in ambient condition and aircraft maneuvers cause distortion into the fan/compressor • Harsh operating environment – high temperatures and large vibrations • Safe operation – avoid stall, combustor blow out etc. • Need to provide long operating life – 20,000 hours • Engine components degrade with usage – need to have reliable performance throughout the operating life Glenn Research Center at Lewis Field Controls and Dynamics Branch

Basic Engine Control Concept • Since Thrust (T) cannot be measured, use Fuel Flow WF to Control shaft speed N • T = F(N) Pump fuel Accessories flow from fuel tank Control Sensor Throttle Measure Compute Meter the Inject fuel Pilot’s produced desired fuel computed flow into power power fuel flow combustor flow request Valve / Fuel nozzle Actuator Yes No Determine Power operating desired? condition Control Logic Glenn Research Center at Lewis Field Controls and Dynamics Branch

Environment within a gas turbine Aerodynamic 2000+ºC 20000+ hours Flame temperature Buffeting Cooling air Between service - 40ºC ambient 120 dB/Hz to 10kHz at 650+ºC 40+ Bar Gas pressures Foreign objects Birds, Ice, stones Air mass flow ~2 tonne/sec 8mm+ Shaft movement 50 000g centrifugal 2.8m 1100+ºC acceleration Diameter Metal temperatures >100g casing vibration to beyond 20kHz 10 000rpm 0.75m diameter Glenn Research Center at Lewis Field Controls and Dynamics Branch

Operational Limits N2 LPC - Low Pressure Compressor HPC - High Pressure Compressor HPT - High Pressure Turbine LPT - Low Pressure Turbine N1 - Fan Speed N2 - Core Speed N1 • Structural Limits: • Maximum Fan and Core Speeds – N1, N2 • Maximum Turbine Blade Temperature • Safety Limits: • Adequate Stall Margin – Compressor and Fan • Lean Burner Blowout – minimum fuel • Operational Limit: • Maximum Turbine Inlet Temperature – long life Glenn Research Center at Lewis Field Controls and Dynamics Branch

Historical Engine Control Fuel flow rate (Wf) or fuel ratio unit (Wf/P3) Safe operating region Max. flow limit Droop slope Proportional control gain or droop slope Required fuel flow @ steady state Min. flow limit Idle Max. GE I-A power power (1942) Engine shaft speed • Fuel flow is the only controlled variable. - Hydro-mechanical governor. - Minimum-flow stop to prevent flame-out. - Maximum-flow schedule to prevent over-temperature • Stall protection implemented by pilot following cue cards for throttle movement limitations Glenn Research Center at Lewis Field Controls and Dynamics Branch

Typical Current Engine Control • Allows pilot to have full throttle movement throughout the flight envelope - There are many controlled variables – we will focus on fuel flow • Engine control logic is developed using an engine model to provide guaranteed performance (minimum thrust for a throttle setting) throughout the life of the engine - FAA regulations provide a maximum allowable rise time of 5 sec to reach 95% and a maximum settling time for thrust from idle to max Glenn Research Center at Lewis Field Controls and Dynamics Branch

Implementing Limits for Engine Control Wf surge Ps 30 blowout R N 2 • Limits are implemented by limiting fuel flow based on rotor speed • Maximum fuel limit protects against surge/stall, over-temp, over- speed and over-pressure • Minimum fuel limit protects against combustor blowout • Actual limit values are generated through simulation and analytical studies Glenn Research Center at Lewis Field Controls and Dynamics Branch

Control Law Design Procedure • The various control gains K are determined using linear engine models and linear control theory • Proportional + Integral control provides good fan speed tracking • Control gains are scheduled based on PLA and Mach number • Control design evaluated throughout the envelope using a nonlinear engine simulation and implemented via software on FADEC processor • Control gains are adjusted to provide desired performance based on engine ground and altitude tests and finally flight tests Math Prob Control Specs Eval Model Form Logic Software Yes Hardware Spec Good to Go & V&V Testing Met? No Adjust Control Gains Glenn Research Center at Lewis Field Controls and Dynamics Branch

Outline • Fundamentals of Aircraft Engine Control • Intelligent Engine Concept – from a controls perspective • Advanced Engine Control Logic • Active Component Control • Distributed Engine Control • Summary Glenn Research Center at Lewis Field Controls and Dynamics Branch

Intelligent Engine Technologies - A Systems Viewpoint - Engine System Controller Actuators PLA + - D T Diagnostics I s o l a t i o n N 1 S 1 O 1 & S 2 O 2 S e n s o r S e n s o r R e a d n i g s E s t i m a t e s Prognostics S 8 N 6 O 8 W e g i h t s Modeling n I f o r m a t i o n I n f o r m a t i o n C o m p r e s s o i n R e g e n e r a t o i n Sensors • Components such as actuators, • Simplified models are essential for sensors, control logic, & diagnostic controller design. Understanding systems have to be designed with the physics of the phenomena is overall system requirements in required to capture critical system mind. dynamics in these models. Glenn Research Center at Lewis Field Controls and Dynamics Branch

Intelligent Propulsion Systems Control System perspective Multifold increase in propulsion system Affordability, Capability Environmental Compatibility, Performance, Reliability and Safety Advanced Health Active Control Technologies Management technologies for enhanced performance for self diagnostic and and reliability, and reduced prognostic propulsion emissions system - active control of - Life usage monitoring and combustor, compressor, prediction vibration etc. - Data fusion from multiple - MEMS based control sensors and model based applications information Distributed, Fault-Tolerant Engine Control for enhanced reliability, reduced weight and optimal performance with system deterioration - Smart sensors and actuators - Robust, adaptive control Glenn Research Center at Lewis Field Controls and Dynamics Branch

Modeling Engine Faults and Performance Deterioration* A general influence coefficient matrix may be derived for any particular gas turbine cycle, defining the set of differential equations which interrelate the various dependent and independent engine performance parameters. Physical Problems Degraded Component Changes in • Erosion Performance Measurable • Corrosion Result in Producing Parameters • Fouling • Flow capacities • Built up dirt • Efficiencies • Spool speeds • FOD • Effective nozzle • Fuel flow • Worn seals or • Temperatures areas Permitting Allowing excessive • Expansion • Pressures correction isolation of clearance • Power output coefficients of • Burned, bowed or missing blades • Plugged nozzles * From ―Parameter Selection for Multiple Fault Diagnostics of Gas Turbine Engines‖ by Louis A. Urban, 1974 Glenn Research Center at Lewis Field Controls and Dynamics Branch

Outline • Fundamentals of Aircraft Engine Control • Intelligent Engine Concept – from a controls perspective • Advanced Engine Control Logic • Active Component Control • Distributed Engine Control • Summary Glenn Research Center at Lewis Field Controls and Dynamics Branch

Recommend

More recommend